Closed Loop Control for Pulsed Laser Deposition System

Integrated thermal, vacuum, and gas-flow subsystems with Python automation for real-time diagnostics, data acquisition, and robust serial communications across Eurotherm, Newport XPS, MKS, Pfeiffer, and Alicat devices.

- Improved reliability and uptime by 20% through systematic troubleshooting

- Unified multi-vendor control with modular Python tooling

- Repeatable runs with monitoring and structured logging

System Components (at a glance)

A quick tour of some of the subsystems that make the PLD control stack work—UI surfaces for operators, motion in-vacuum, and the electronics that tie it all together. These components enable reliable, repeatable runs with clear feedback and safety interlocks.

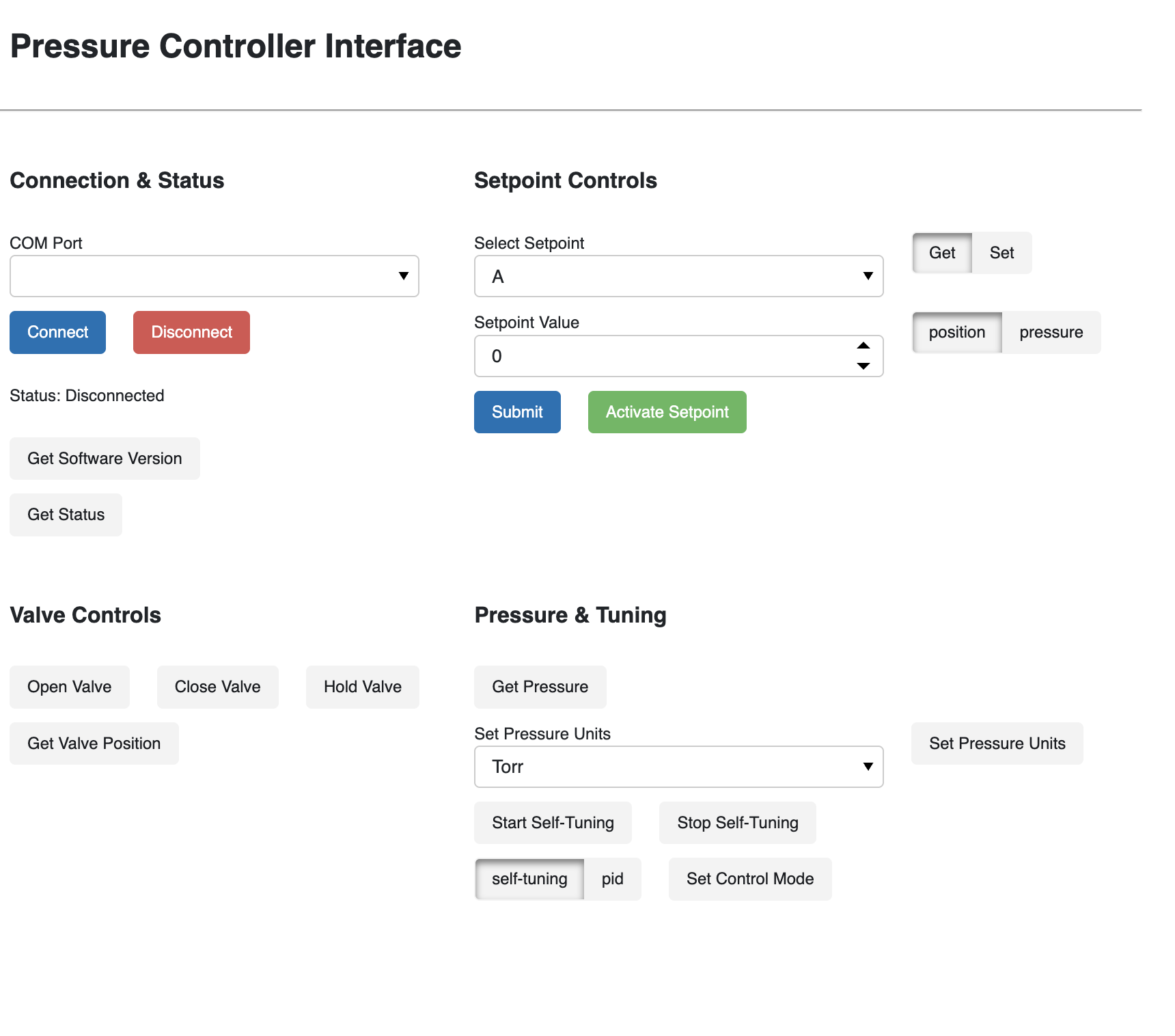

Pressure Controller UI: Real-time chamber pressure, setpoints, PID status, and trend plots—built for quick tuning and safe transitions.

Target Carousel (video): Vacuum-compatible, stepper-driven indexing for precise target changes and consistent rastering between runs.

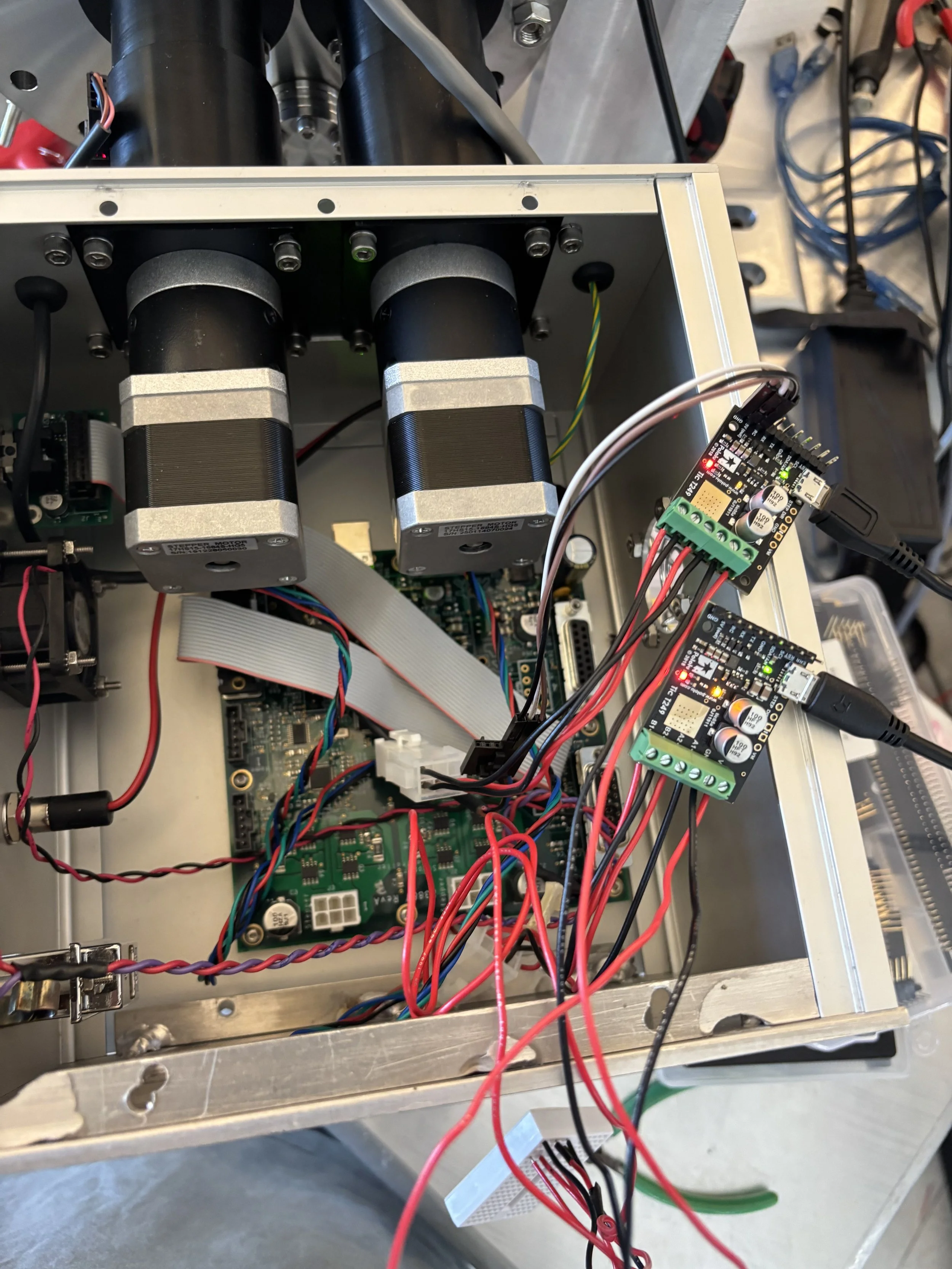

Stepper Controller Prototypes (photo): Modular driver boards and wiring harnesses with indicators for fast bring-up and troubleshooting.

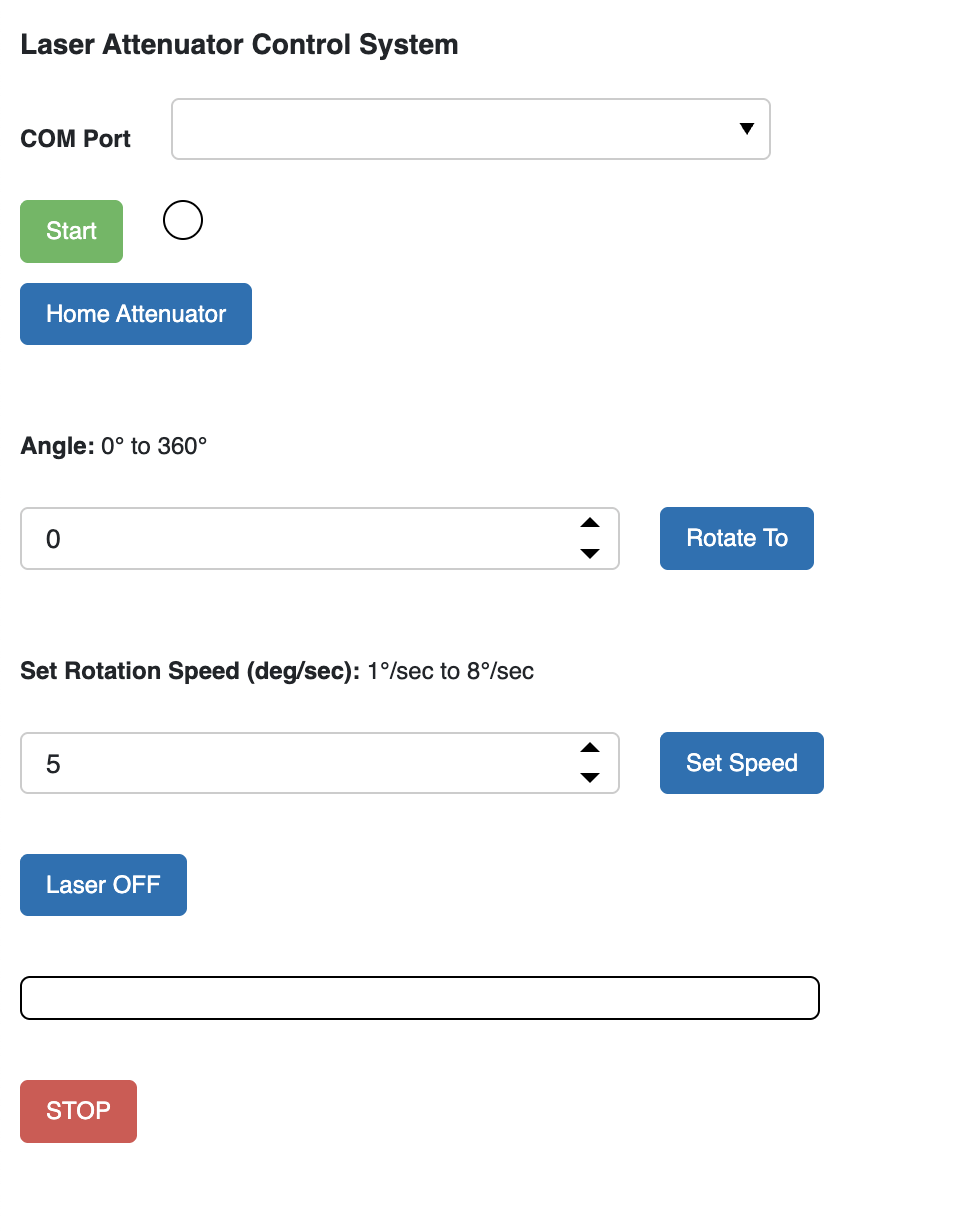

Laser Attenuator UI: Fine fluence control with shutter motion for safe laser operation.

(Each media item illustrates a different layer of the closed-loop system: sensing, actuation, electronics, and operator control.)

Rotating targets in vacuum chamber.